| More on Burners: |

| Why the Giberson Ceramic Burner Head was invented? |

| The Giberson Ceramic Burner Head was invented in response to a compelling need. The burner systems used in the early years, beginning with the Toledo Workshops (1962), were made from a collection of pipe parts, soft brick, and a Dayton blower. You could certainly melt glass with a system like that but it was noisy, could easily burn back into the pipe structure, and it blew smeg and metal scaling onto the molten glass. |

|

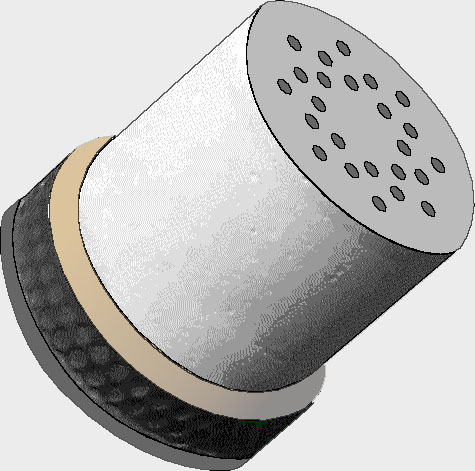

The Solution: Within a few months of setting up my studio back in 1968, I saw the compelling need for an improvement in this burner area. I set about developing a better mixer with a retention nozzle. The retention nozzle in itself made a quieter work environment. The retention nozzle creates an organization to the burning gases. By changing the hole pattern I could make a long, skinny, lazy (luminous) flame or a short bushy radiant flame. And by using many holes verses just a few holes I could make it have a quieter burn. With this new concept for the burner nozzle I developed several new patterns, but as these were made of mild steel they did not survive long in the intense heat of the glass melting atmosphere. Every few weeks I was back at it making a new head for my furnace. Then out of the blue the idea struck me to make a ceramic head. This I did and it worked great: I replicated the patterns I had made previously in metal. |

|

| Once the burner was invented, I applied for and got my first patent. I dubbed the burner "The Giberson Ceramic Burner Head." It is U. S. Patent #3697000. For years I struggled along. Occasionally a glassblower would wander into my studio and be amazed at the quiet burn and the efficient flame. That's how I sold my burners, usually one at a time to people who saw them in action and wanted one for themselves. In all of my years of making these wonderful burner heads I have not spent much time or energy on advertisement. It has been a word of mouth operation. |

| Here is a schematic of a homemade air/gas mixer with a "Giberson Tip" (Giberson Ceramic Burner Head). This would be used on low pressure natural gas or low pressure propane gas. |

|

| The obvious advantage to this mixer is you can make it yourself. This is an Alfred Mixer (named after the prestigious Ceramics College, ALFRED UNIVERSITY, where it was developed for use by potters). It is constructed using 1-1/2" black iron pipe fittings: a "Tee" and a couple of nipples. There are other configurations of the same pipe parts to achieve a similar effect. However, please read my paper on how to make my preferred version of this Alfred Mixer and adapt it to the Dayton Blower to make a functional Gas/Air Mixer for low pressure gasses. |

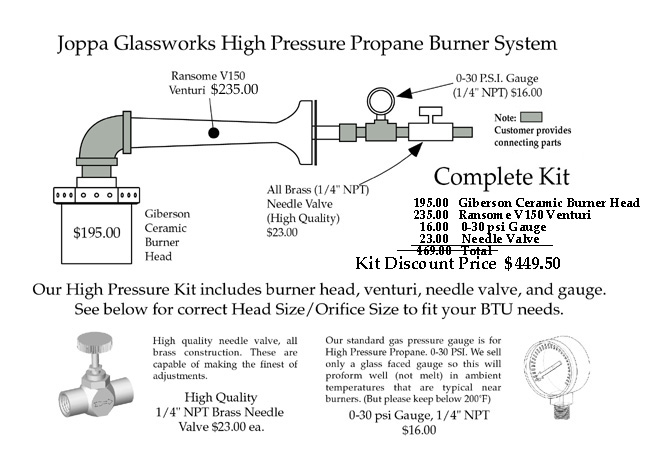

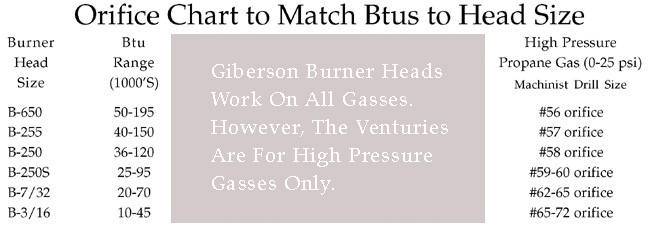

| HIGH PRESSURE PROPANE SYSTEM: There is one more burner system that you might be interested in. This is a venturi mixer/ Giberson Tip combination that does not rely on electricity to operate. This makes it very appealing for the back to the woods type of crafts person. This is the very first successful burner/mixer combination that I put together. The only part of this that I make is the "Tip" but I sell the whole package. There are hundreds of furnaces out there running quietly on this sweet little combination. (BEFORE ORDERING, PLEASE READ ABOUT THE DIFFICULTIES OF GETTING HIGH PRESSURE PROPANE INSPECTED BY YOUR LOCAL GAS INSPECTOR. ) |

Venturi Mixer for HIGH PRESSURE PROPANE (0-25 PSI) |

| Complete Venturi Mixer with Giberson Head: The kit includes a venturi, Giberson tip, needle valve, and gauge. $449.50 (The parts indicated as gray must be purchased from a hardware/plumbing supply) |

|