| A history of the Classic Giberson Head: In the mid 1970s I discovered a company in Wisconsin which made metal stampings and by working with their team I designed a metal backplate for my ceramic burner production. Essentially this was a perforated metal backplate with a threaded 1-1/2 inch coupling in the center. What was great about this is I did not have to start from scratch, but used dies already in the factory inventory. This was the cornerstone for my round-backed "Classic Giberson Head". I was able to purchase these parts at a reasonable price and this romance lasted a good long time until POOF! In the middle of this last July (2017) the company disappeared into obscurity. Not a trace. I scurried around like a crazy person to find a replacement solution, but the expense of cutting new dies and absorbing set-up fees were prohibitive for this little operation of mine. Perhaps I could have develop something from China as almost all of this business has moved there, but I should mention I hate the idea of Chinese outsourcing. I am not a political wacko, but for me, I wanted this made here. Even simplier: I wanted to have control of this production process even if it meant I would have to do the welding. |

This Round Backed Classic Giberson is no longer being made. |

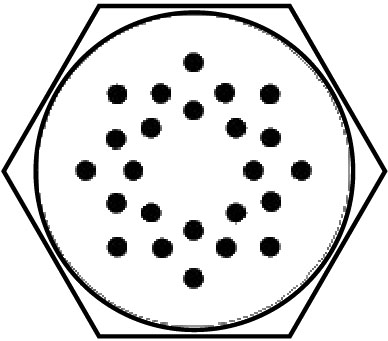

| The Summer of 2017 was total chaos. Our burner manufacturing revolves on a yearly cycle with Summertime being the time for making the castings, but without any real idea of what the new burner would look like this phase of production had to be put on hold. Mid-September I made the decision to make all of this in the USA using modern available technology. I hired a laser cutting company to make hundreds of parts and prevailed upon a local machinist to make threaded couplings. I built bending dies and bought a new welder. Out of this came my new masterpiece, the new kid on the block: The Hexagonal Backed Giberson Ceramic Burner Head. |  |

Here is a comparison of the two Burners side by each: The flange part is pretty much the only part of this that is different. The pin plates and the front of the burners are still made in the same metal molds that I have used for years. The cores are also the same. Essentially this is a direct replacement and the only thing different is the last 1 inch of the backplate. I hope you enjoy using these new beauties. We will even use the same model numbers: 650, 255, 250, 250S, 7/32 and the 3/16. Because of resent increases in materials costs our new heads will sell for $195.00. We hope you will be pleased with our new burner design. Please direct any comments or concerns you may have to me, Dudley Giberson, at 603-456-3569 or e-mail at joppaglass@conknet.com |

|